Overview CC 3000 / VCC 3000 Continuous Casting Machine

Download technical data [PDF]

Quattro Drive system

Easy to control by LCD display

Blue Power Continuous Casting Machine CC 3000 with optional flying saw

Flying saw (option)

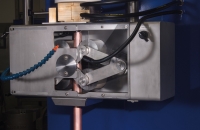

CC 400 with hydraulic cutter (option)

The optional hydraulic scissors cut the material into sections during drawing

Technical data CC 3000 / VCC 3000 Continuous Casting Machine

| power | |

| power max. / electrical connection | 30 kW 3x400 V |

| temperature max. | 1500° C |

| capacity | |

| crucible volume | 3.400 ccm = 27 kg Cu * |

| wire/tube production up to | ø 40 mm ** / ø 85 mm ** |

| sheet production up to | 130 x 12 mm |

| handling and control | |

| 100 programs selected by | LCD display full text readout |

| vacuum/inert gas overpressure | CC 3000 / VCC 3000 |

| neutral inert gas atmosphere | |

| optical die temperature measurement | |

| die cooler with protective gas flushing | |

| secondary cooler | |

| end bar sensor | |

| quality management | |

| RS 232, diagnostic system | |

| data printer | |

| GSM modem for remote service | |

| accessories | |

| Quattro drawing unit | |

| center alignment | |

| sinter kit | |

| granulating tank | |

| bending unit | |

| simultaneous casting of several wires | 5 wires *** |

| flying saw | |

| hydraulic cutter | |

| * liquid metal up to top level of the crucible | |

| ** Standard sizes – special dimensions or profiles for watch cases etc. on demand | |

| *** not in combination with Quattro Drive | |

= standard equipment | = not available | = optional

All machine descriptions and technical data published on this site make no claim to be complete. They are subject to change and therefore they are not basis of contract.