High-tech in most compact size.

The MC series vacuum pressure casting machines are compact yet highly professional casting systems for Rapid Prototyping studios and laboratories. They offer extremely short processing time from mould manufacturing to completed casting; simple, safe operation; high quality and reproducible casting results.

- NEW: The MC 16 for the very fast and uncomplicated casting of single models in high quality and every metal, even in steel or platinum.

- The MC 60 for the production of smaller casting trees in gold, silver and other special jewellery alloys, aluminium, copper and other metals.

- The MC 20 V with the Indutherm vibration system, programm control and LCD-display for high quality jewellery casting especially in platinum, palladium or steel.

- The MC 100 V also with the Indutherm vibration system, programm control and LCD-display for the production of larger casting trees particularly in platinum, palladium or steel.

With the MC machines, you can easily cast by hand from the crucible to your mould and feel what you are doing – just as it has been done for thousands of years. So that this works consistently and safely, the entire melting/casting unit is tilted together through a 90° angle. For perfect balance and to make do with as few moving parts as possible, almost the whole machine moves during tilting: being cylindrical in design, the whole moving section rotates as if in a halfpipe – ingeniously simple and stylishly designed on high-quality rollers. However, unlike manual casting, the process takes place in an enclosed chamber under a vacuum or inert gas atmosphere, to prevent air pockets and oxidation. You can check the melting and pouring-off process through the sight glass.

Why did we not just make one of the tried and tested machines in the VC range smaller?

There are actually machines on the market in which the construction principle of larger machines has been miniaturised, and which therefore work with a sealing rod system. We prefer the tilting casting system for the following reasons:

Small crucibles with sealing rods are hard to fill. Generally only granulate or some other ground material can be poured in; the sealing rod gets in the way with larger pieces such as manufacturing residues, sprue etc. Naturally the pouring-off opening is also very small with small crucibles. This makes viscous alloys hard to pour out, leading to the formation of incrustations and consequently leakage. This makes the service lives of expensive consumables extremely short. The crucibles in our MC machines are not only cheaper – they can also be used for a substantially longer time. Pouring off into the mould is extremely simple.

The number of mechanically moving parts and seals – so all wearing parts – is substantially smaller with our tilting principle, reducing your running costs.

The viewing glass and open design enable you to keep an eye on the melting and casting process and control it perfectly.

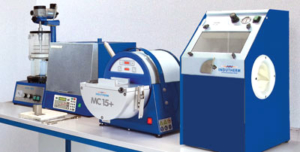

We also offer complete equipment.

On the table on the left: Vacuum investment machine for bubble-free mixing of the investment compound and filling of the flask. The integrated vibrator eliminates any possible airlocks. The 1100°C furnace for melting out the wax and burn-out the form. Mini casting machine, here the MC 15+, which is supplied now by our new MC 16. Sandblasting cabinet for easy removal of plaster.

{module id="123" showtitle="true"}