The Blue Power Continuous Casting Machines – the only ones available with vacuum and/or quattro drive.

More flexibility, lower costs

Blue Power continuous casting machines help you to save production costs. With only one machine, you can produce your own alloys or semi-finished products in different shapes and sizes in the shortest time, for example:

- wires or bars in every diameter you need, up to ø 85 mm (CC 1000/3000)

- sheets and strips, e.g. ring production, for stamping and pressing

- tubes, perfect as basic material for cutting in sections for wedding ring production

- granulates

As the desired parts and alloys can be produced within minutes, you can reduce your investment for material in storage. Your processes will get faster, more flexible and more efficient. With optionally available equipment as for example sintering set for diffusion bonding and granulation tank the versatility of these machines may be enhanced even more.

Semi-finished materials in highest quality

To reduce the risk of oxidation during melting and during drawing, the new machines are equipped with inert gas function, vacuum system for the melting chamber (VCC), optical die temperature

measurement, die cooler with inert gas flushing and additional secondary cooling system. All these measures are ideal especially for alloys containing copper as these materials tend to oxidise easily. Degasification under a vacuum results in a substantially improved – because of the absence of oxidation – semi-finished product.

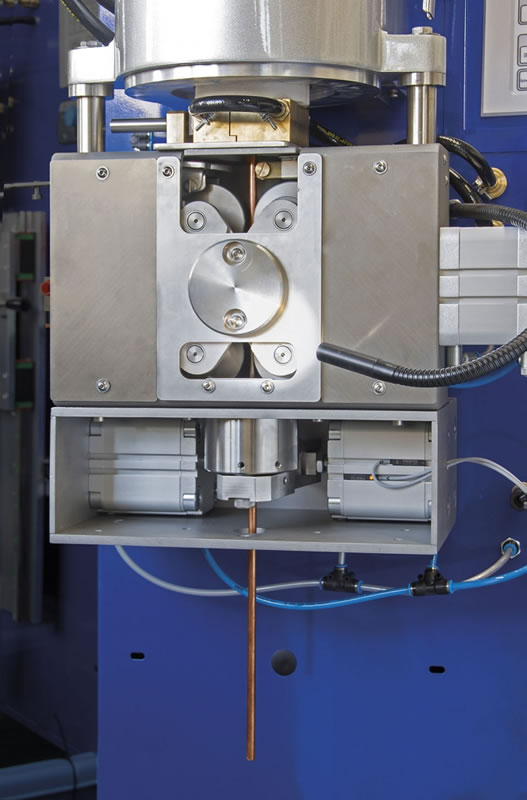

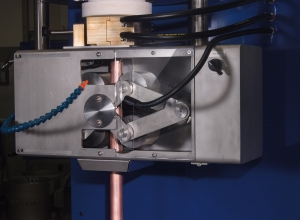

Optional quattro drive system

The optional drawing unit with four instead of two motor driven feed rolls produce smoother tubes and sheeting with reduced marks of transportation. This system is available for each CC or VCC machine.

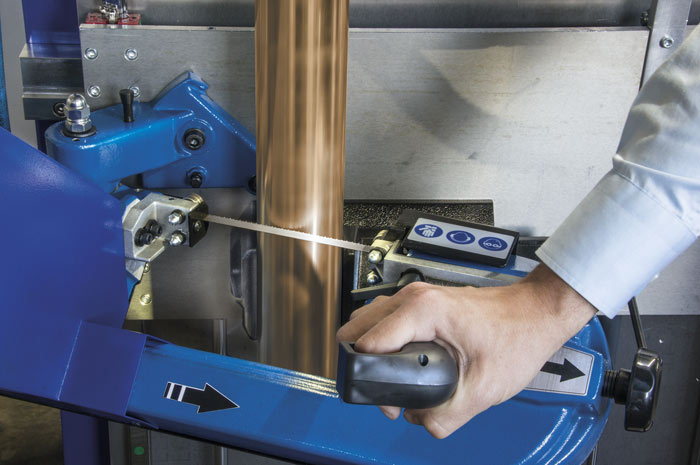

Many options for an efficient production process, e.g. hydraulic cutter, flying saw and more