Overview Gas Atomizers AUG 1000 – AUG 28000

Powder particle size for every request

The BLUE POWER atomisation plants have been particularly designed for the flexible and economic production of small-scale metal powder batches. Traditional large-scale production plants cannot provide this economic advantage. Frequently changing alloys in production require high cleaning efforts to avoid cross contamination. Particularly in R&D or precious metal powder applications small amounts of various kinds of powder are frequently required, often also new types of alloy powder not available on the market. Especially fast developing applications like SLM and MIM require more and more specialised metal powder.

High quality metal powders

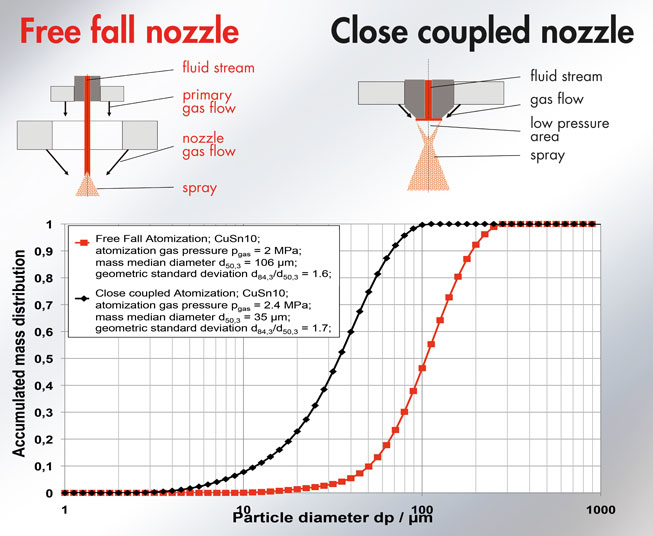

Our atomisers produce spherical, flowable metal powders with mean particle sizes between ~1 and 200 µm for e.g. additive manufacturing, soldering or foam sintering processes, as well as MIM and other powder metallurgy procedures. To obtain specific metal powder characteristics, the AU machines work with different easy-to-change nozzle systems: free fall and close coupled atomisation nozzles. Flow optimisation in the spray chamber ensures an increased powder quality (avoidance of satellites).

Download technical data [PDF]More about Gas Atomizers AUG 1000 – AUG 28000

The BLUE POWER Atomisers are developed especially for flexible and economic production of small to medium scale / high value metal powder batches.

AUG series – advantages

For a wide spectrum of alloys , e. g. Ag, Au, Cu, Sn, Fe, Co, Ni, Pd, Pt …

Inductive heating

in graphite crucibles, depending on the alloy additionally with ceramic insert crucibles, up to 2000°C

Four different versions offering crucible volumes from 1.5 – 28 l

AUG 1000, AUG 3000, AUG 12000, AUG 28000

Anti-oxidation features

The AU machines offer the possibility of oxidation-free processing in the closed-chamber machine by means of de-gassing, vacuum and

protective gas features.

Gas flow optimisation

Increase of powder quality by gas flow optimisation in the spray chamber (avoidance of satellites)

Specific powder characteristics

by use of different atomisation nozzles and optional use of hot spray gas

Modular availability of free fall as well as close coupled atomisation nozzles to obtain specific metal powder characteristics. Fast and easy nozzle change.

Easy-to-clean concept

Polished stainless steel surfaces prevent powder adhesions in spray chamber, cyclone and collector – all parts are easy to clean without any residues.

Dynamic Differential Pressure system for constant metal mass flow

The DDP system is ensuring a constant and controllable metal mass flow, and therewith gas-to-metal ratio, independent from the melt level in the crucible.