Overview MC 16

The tabletop casting machine MC 16 is the new MC series basic model

- New: Run of process with controller

- New: LCD-display with all program data

- For graphite and for ceramic crucibles, temperature up to 2000° C

- Very easy to use, short training period

- Perfectly suited for small castings and small series

- 3.5 KW induction heating for fast heating and high maximum temperature

- Even for the casting of steel and platinum

- Fast process time thanks to short heating period of the flasks

More about MC 16

The new MC 16 tabletop casting machine is developed for the requirements of laboratories, casting studios and product designers. The main advantages:

- extremely short processing time from model to casting

- temperature up to 2.000° C, suited for a wide range of metals and alloys, even for steel or platinum

- now with program control and LCD display for very safe and simple use

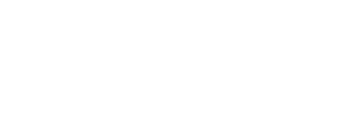

- automatic vacuum and overpressure, excellent form-filling by overpressure up to 2 bars

- protective gas supply

- low running costs because of inexpensive crucibles

The 3.5 kW induction heating means that the material melts very rapidly in an atmosphere without oxidation. All metals – also platinum and steel – can be cast without difficulty. The crucibles are large enough to solve any standard casting task one would find in a studio or atelier with no difficulty at all. The flasks can also accommodate larger or heavier jewellery parts. It is equally possible to melt and cast minimal amounts of metal.

Rapid and simple casting

The whole process of casting can be carried out simply, quickly and safely without any real prior technical knowledge of casting. With the MC 16 – and with all other MC machines – you can easily cast by hand from the crucible to your mould and feel what you are doing – just as it has been done for thousands of years. So that this works consistently and safely, the entire melting/casting unit is tilted together through a 90° angle. For perfect balance and to make do with as few moving parts as possible, almost the whole machine moves during tilting: being cylindrical in design, the whole moving section rotates as if in a halfpipe – ingeniously simple and stylishly designed on high-quality rollers. However, unlike manual casting, the process takes place in an enclosed chamber under a vacuum or inert gas atmosphere, to prevent air pockets and oxidation. You can check the melting and pouring-off process through the sight glass.

The whole process of casting can be carried out simply, quickly and safely without any real prior technical knowledge of casting. With the MC 16 – and with all other MC machines – you can easily cast by hand from the crucible to your mould and feel what you are doing – just as it has been done for thousands of years. So that this works consistently and safely, the entire melting/casting unit is tilted together through a 90° angle. For perfect balance and to make do with as few moving parts as possible, almost the whole machine moves during tilting: being cylindrical in design, the whole moving section rotates as if in a halfpipe – ingeniously simple and stylishly designed on high-quality rollers. However, unlike manual casting, the process takes place in an enclosed chamber under a vacuum or inert gas atmosphere, to prevent air pockets and oxidation. You can check the melting and pouring-off process through the sight glass.

Technical data MC 16

| power | |

| power max. / electrical connection | 3.5 kW 230 V single phase |

| temperature max. | 2000° C |

| temperature control | thermocouple Type N up to 1.300° C |

| thermocouple Typ S up to 1.600° C | |

| capacity | |

| casting volume | 60 g Cu |

| 110 g steel / 200 g Pt | |

| for use of flasks | up to ø 30/50/65/80 mm x 80 mm H |

| Handling and control | |

| control panel | digital display |

| automatic vacuum function | |

| automatic overpressure function | |

| vacuum or overpressure after casting | -1 up to +2 bar |

| washing by inert gas | |

| vibration system | |

| supply: cooling water, inert gas argon or nitrogen | |

| temperature measurement/control | bis 1.300° C / bis 1.600° C |

| quality management | |

| RS 232, diagnostic system | |

| GSM-modem for remote service | |

| accessories | |

| vacuum investment mixer Indumix 2 | |

| furnace AK 20, 1,100°C | |

| sand blasting cabinet vacuum pump fl r unit | |

| vacuum pump | (min. 8m3/h) |

| floor unit | |

All machine descriptions and technical data published on this site make no claim to be complete. They are subject to change and therefore they are not basis of contract.