Overview VC 1000 V Vacuum Pressure Casting Machine

For casting of larger parts

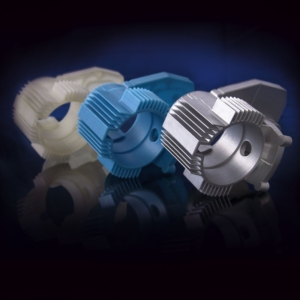

With a flask size of Ø 250 mm x H 500 mm the VC 1000 V is the smallest of the large volume VC series machines. VC 1000 V, VC 3000 V and VC 12000 V are always the first choice for casting of large parts with complicated geometry or when the number of pieces is not large enough for die-cast production. They offer the best pre-conditions for high quality castings in aluminium: the hydrogen content of aluminium alloys may be adjusted by regulating the vacuum during melting…

Download technical data [PDF]More about VC 1000 V Vacuum Pressure Casting Machine

VC 1000 V Vacuum Pressure Casting Machine with program control and vibration system: for high-quality castings in aluminium and other metals

VC 1000 V, 3000 V and 12000 V offer the best pre-conditions for high quality castings in aluminium: the hydrogen content of aluminium alloys may be adjusted by regulating the vacuum during melting. This way, foaming of molten metal can be avoided without any melt additives. Overpressure in the melting chamber during and after casting and simultaneous vacuum in the flask chamber optimise form filling especially in filigree or thin-walled areas.

All our large VC machines are now equipped with a new program control system. The casting process is controlled via LCD full text display. Complete casting cycles may be stored for repeatable castings. As the most important innovation, all large VC machines use the vibration technology for improved form filling and casting quality.

Magnesium casting versions

The magnesium casting versions are constructed according to strict safety requirements and guarantee safe and easy casting of magnesium – and of course of many other metals, too.

Technical data VC 1000 V Vacuum Pressure Casting Machine

| power | |

| power max. / electrical connection | 25 kW 3x400 V |

| temperature max. | 1500° C |

| capacity | |

| crucible volume | 1.500 ccm = 4 kg Al * |

| for flasks up to | ø 250 mm / 500 mm H |

| handling and control | |

| program control (100 programs) | |

| automatic flask lift | |

| dual temperature control | |

| flask temperature measurement | |

| quality management | |

| RS 232, diagnostic system | |

| data printer | |

| GSM modem for remote service | |

| accessories | |

| granulating tank | |

| magnesium kit | |

| * liquid metal up to top level of the crucible | |